Mature, stable and fully functional: PlanMateAPS has been on the market for more than 10 years. It is a powerful, mature and stable APS system that has been verified by a large number of successful cases. The main members of the team are familiar with the manufacturing industry. Through years of experience accumulation, PlanMateAPS’s models and algorithms can cover the main production processes of the manufacturing industry, adapt to the needs of various industries through flexible modeling and system parameter configuration, and also support secondary development for special needs. The system’s automatic scheduling results rarely require manual modification.

Powerful operating software: The production site situation is changeable, various abnormalities occur frequently in the workshop, machine failures, mold failures, quality problems, material problems, temporary orders, etc. all require modification of the plan. PlanMateAPS is currently the most user-friendly APS system on the market. Its intelligent Gantt software is powerful and easy to operate. Planners can perform plan inspection, analysis, modification, progress tracking, exception handling and other operations in a very intuitive way. , so that the plan is highly consistent with the site.

System integration and modeling: The model structure is reasonable, comprehensive, and easy to understand. The modeler is easy to operate. Users can quickly model in a variety of ways. It supports Excel import or process data import from other systems. Open system architecture makes it easy to integrate with various MES and ERP systems.

Rich experience and strong implementation capabilities: The company’s main personnel are familiar with the manufacturing industry, understand customer needs, and are familiar with various ERP and MES systems. They can skillfully conduct secondary development and quickly introduce systems according to actual customer needs. Currently, there are mature solutions in electronics, plastics, machinery, hardware, furniture, clothing and other industries.

High cost performance: PlanMateAPS has stable performance, mature products and easy introduction. With a strong local development and implementation team, the implementation cost is lower than similar imported software (similar performance and functions). With reasonable fees and flexible payment methods, even small and medium-sized enterprises can import APS. The supporting MRP system and mobile reporting tool software enable companies without MES systems to import APS. Complete authority control and security management strategies are suitable for large international enterprises.

PlanMateAPS import revenue

| Appraisal items | Import revenue |

| Planning accuracy | The average is 70% before importing, and the average is 90-95% after importing. |

| On-time delivery rate | The average is 80% before importing and 90% after importing. |

| Equipment utilization | Increase 5-10% |

| Unnecessary switching (mold change, color change, product model change, etc.) | 10% reduction |

| Plan achievement rate | An average of 80% before import and an average of 95% after import |

| Inventory occupancy cost | Reduce 10-30% |

| Production shortage | 30-50% reduction |

| PMC manpower saving | 70% reduction |

| Communicate and coordinate time savings between departments | 80% reduction |

| Quantity of work in progress | 70% reduction |

| Working hours for multi-process products | 50% reduction |

Just listening to the product introduction and watching the PPT cannot guarantee the successful introduction of the APS system. If you want to reduce the risk of system introduction and ensure successful launch in the future, it is best to give it a try.

Due to the complexity of the APS system, it takes too long to install and learn to use it yourself, and it is easy to give up halfway. POC (logical verification-use your own data to let the manufacturer demonstrate) is the best way to test.

If you are interested in evaluating the APS system, please leave us a message to request a system demonstration. We will arrange product demonstrations of similar cases based on your industry and needs.

If the basic functions meet your needs, we will give POC suggestions after the system demonstration and guide you to collect your own verification data (Excel)

After receiving the POC test data, we will complete the demonstration of the POC verification plan within 2 weeks

We will discuss the POC results together, define your requirements in detail, and provide feasible solutions to ensure that the system covers your key requirements

You can send the collected POC data to multiple alternative system suppliers at the same time, evaluate the POC test results of each manufacturer, and choose the system that best suits you.

Work order management

- Order work order matching

- Multi-level work order matching

- Components and Assembly Collaboration Program

- Reduce inventory and ensure complete assembly

All material analysis

- Analysis of complete set of work orders

- Allocation of materials in inventory and in transit

- Refined daily material requirements

- Create a purchasing referral program

Delivery date assessment

- Quick order evaluation and delivery time

- Improve on-time delivery rate

- Capacity analysis improves predictability

- Assess the impact of changes in delivery schedules

Detailed plan

- Automatic scheduling is accurate

- Improve equipment utilization

- Improve production efficiency

- Facilitate performance management evaluation

Data sharing

- Integrate with ERP and MES

- Release production plan to MES

- Data sharing via the web

- Improve work efficiency

Plan modification

- The graphical operation is intuitive and convenient

- Plan to view modification tracking progress

- Quickly rearrange to respond to changes in demand

- Comprehensive evaluation of optimization plan

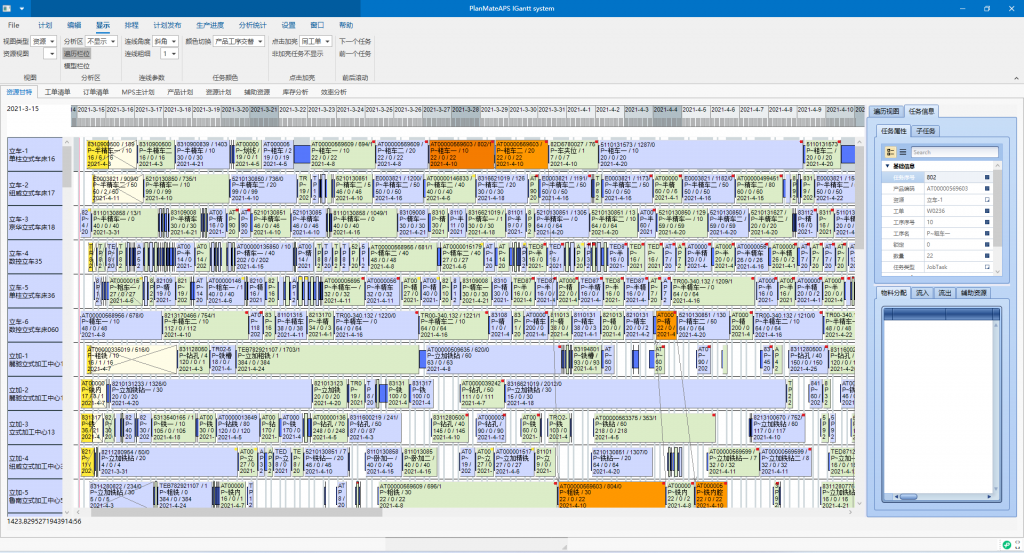

Visual operation

Mature Gantt chart software with powerful analysis and editing functions

Facilitates plan analysis and modification, and flexibly responds to various needs in the workshop

Customized solutions according to customer needs

Strong development team, designing solutions according to customer needs

Integrate with various ERP and MES systems

mature product

The product is mature and the implementation team is experienced

Familiar with the manufacturing industry to ensure successful introduction

More than 10 years of system implementation experience

Strong industry adaptability

The system operates stably and has comprehensive functions

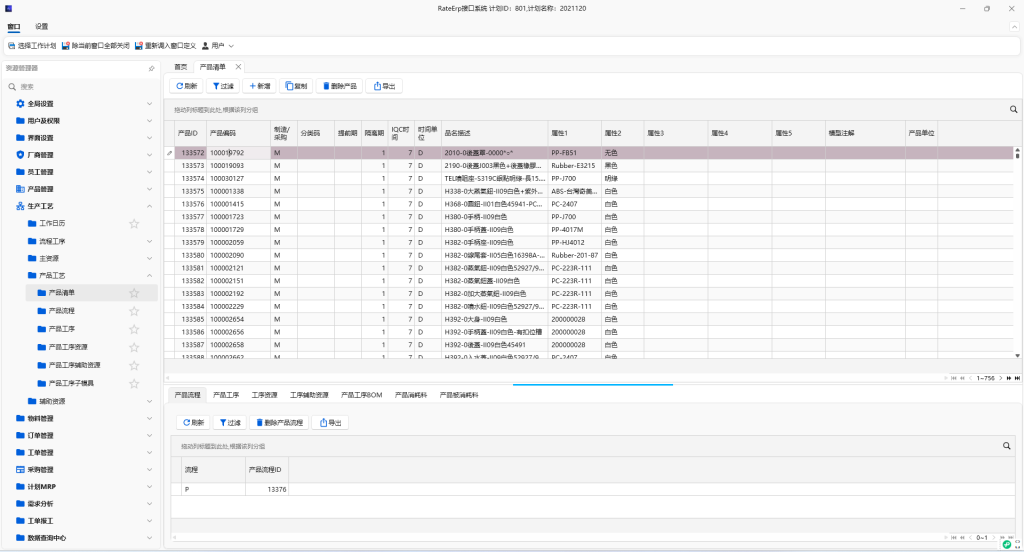

Rate product structure

Focus on supply chain optimization

Advanced scheduling-APS

PlanMateAPS is an advanced production planning and scheduling system with powerful algorithms that meet the needs of multiple industries. It can be customized according to customer needs, and production scheduling results rarely require manual adjustment.

Interactive intelligent Gantt chart software is used to facilitate customers to comprehensively view and analyze production plans, quickly modify plans, and flexibly respond to exceptions.

PlanMateAPS integrates with the customer’s ERP and MES systems when imported. Enterprises that have not imported ERP can use Ruite Technology’s production management software to manage work order requirements.

Mobile reporting APP

Ruite Technology’s mobile reporting APP provides a workshop production reporting solution for companies that have not imported MES systems, so that companies that have not imported MES can also import APS.

The work reporting APP receives APS scheduling results and has permission management. Authorized personnel can select equipment to report production progress.

The reporting results can not only be used to track progress with APS, but can also be used as the basis for piece-rate wages.

Production management system

RateMRP provides complete production management solutions for enterprises that have not introduced large-scale ERP. System functions include:

- Process modeling, sharing modeling tools with APS system

- Sales order entry, production work order creation, production progress tracking, completion warehousing, work order completion, sales outbound

- Order work order management uses limited capacity algorithm to calculate MRP to generate material requirements plan.

Ruite Technology’s production management function module can also be used as a plug-in module for other ERP systems to refine material requirements and optimize material management.

About Rate Technology

We come from a software team that has been focusing on APS development and research for 10 years

When Shenzhen Ruite Technology Co., Ltd. was founded, it provided CAM solutions for the PCBA industry and developed auxiliary programming optimization for SMT, AI, ICT and other equipment. In the PCBA industry Have many customers.

The company focuses on the development of a fully automatic scheduling system-PlanMateAPS, which is an industry-customized automatic scheduling software, production scheduling software, production reporting software, and APS scheduling software. , intelligent production scheduling system, small and medium-sized enterprise production management system, small and medium-sized enterprise ERP system, automatic production scheduling, APS production planning and scheduling, master production planning, MRP customized development, with customers in Guangdong, Jiangsu, Zhejiang, Shandong, Fujian, Beijing, Shanghai, Tianjin and other parts of the country.

With the demand for refined production in the manufacturing industry, the need for production scheduling is becoming increasingly urgent. Ruite Technology introduced software technology from Israel and coupled with many years of experience in the manufacturing industry, independently developed the PlanMate advanced production scheduling system to provide production scheduling solutions for the manufacturing industry.

Based on rich on-site experience in the PCBA industry and a full understanding of customer needs, PlanMate has entered the market starting from the PCBA industry. Currently PlanMate has mature solutions and successful cases in large PCBA/SMT companies.

Following the maturity of the PCBA industry, PlanmateAPS has launched industry solutions for machining, injection molding and other industries.

The main technical personnel of Ruite Technology have long-term working experience in the manufacturing industry, are familiar with Chinese enterprises, focus on the flexibility and practicality of products, and have mature experience in various changes and abnormal events within the enterprise. The solution is more suitable for Chinese enterprises.

PlanMateAPS provides different solutions for large enterprises and small and medium-sized enterprises to adapt to the different needs of customers.