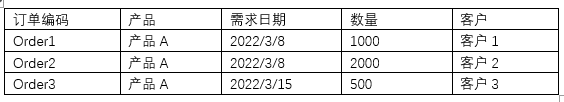

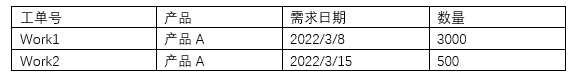

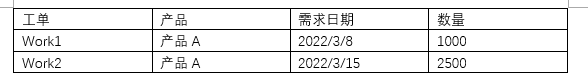

The demand management module of PlanMateAPS has an order and work order matching function. After matching calculations, work order splitting suggestions will be given based on the matching results. As in the above example, Work1 can be split into two work orders with quantities of 1000 and 2000. Work order splitting recommendations need to consider several parameters:

1: Difference in demand dates (if the difference in demand dates is less than the set value, it will not be split)

2: Remaining quantity (if the quantity of the last work order is very small after splitting, it will not be split)

After APS gives the split suggestion, it needs to carry out the actual split in ERP, and then re-run the matching after the split.