Model structure of PlanMateAPS

PlanMateAPS is a universal automatic production scheduling system. The optimizer schedules according to the process model, and the scheduling rules, optimization methods, etc. are controlled by parameters. All models are saved in the database.

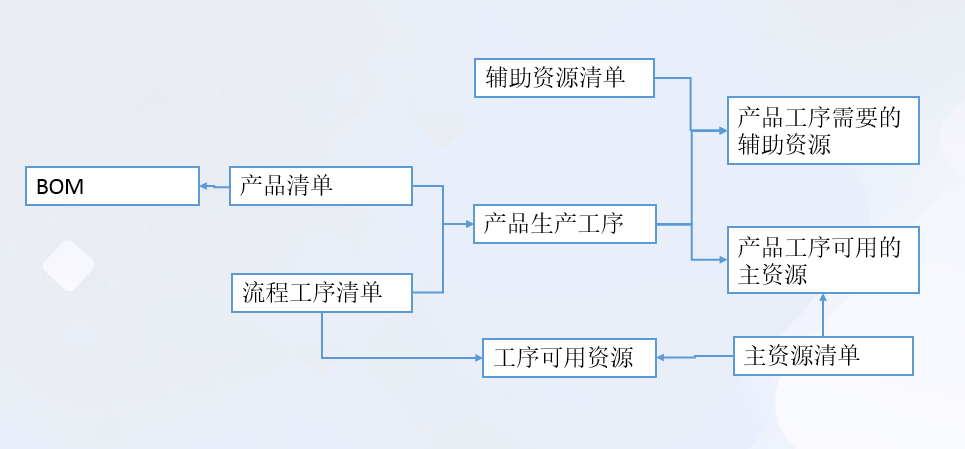

PlanMate’s model structure:

PlanMate’s model consists of basic objects and relationships between objects.

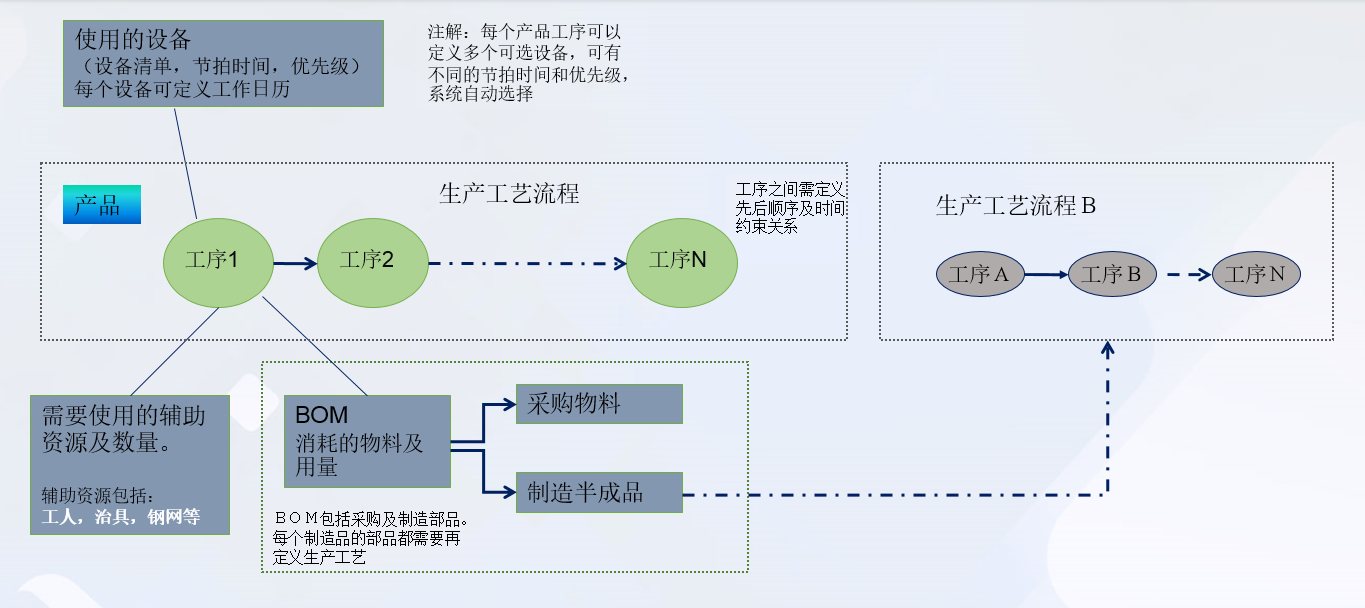

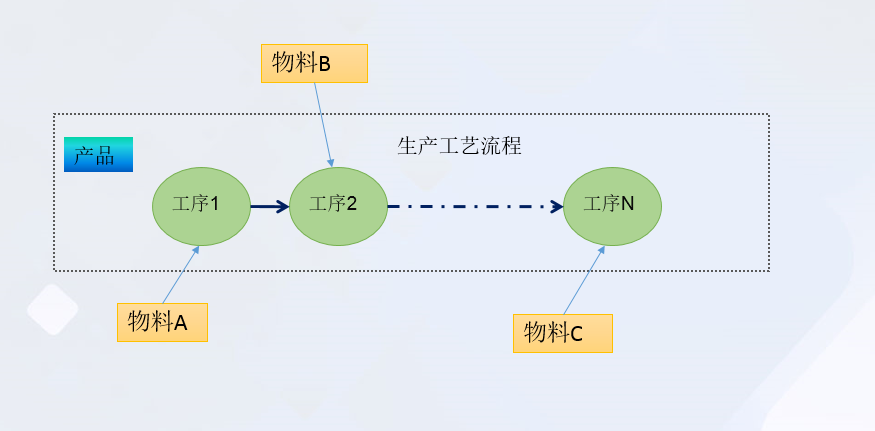

Product production process:

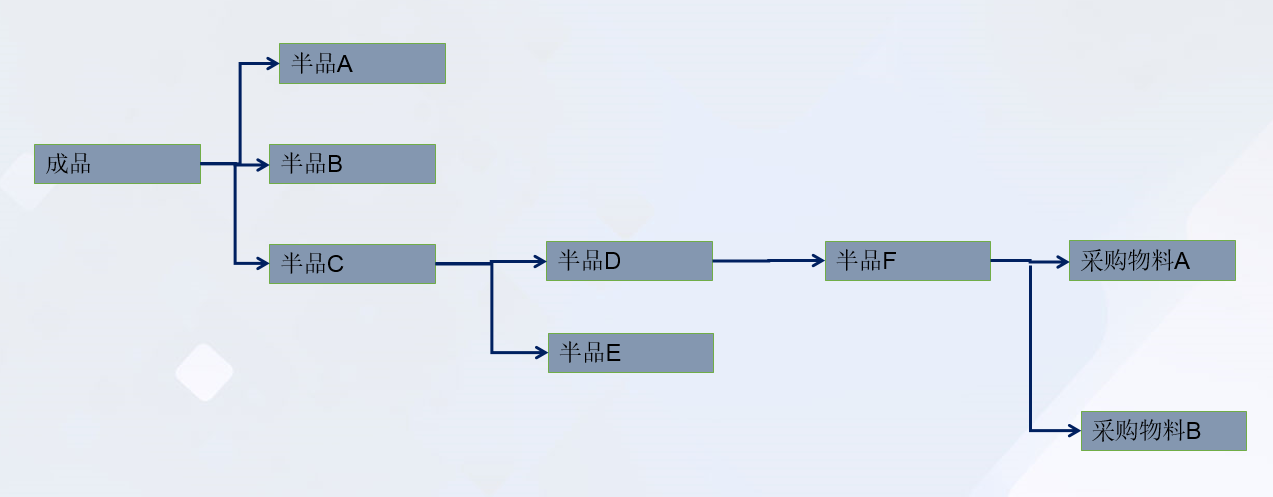

BOM structure:

PlanMate supports multi-level BOM. Users only need to place an order for finished products, and the system will automatically expand the BOM to calculate the demand for semi-finished products, and optimize the schedule for both semi-finished products and finished products.

PlanMate also supports process-refined BOM, and materials can be added at different nodes of the process.

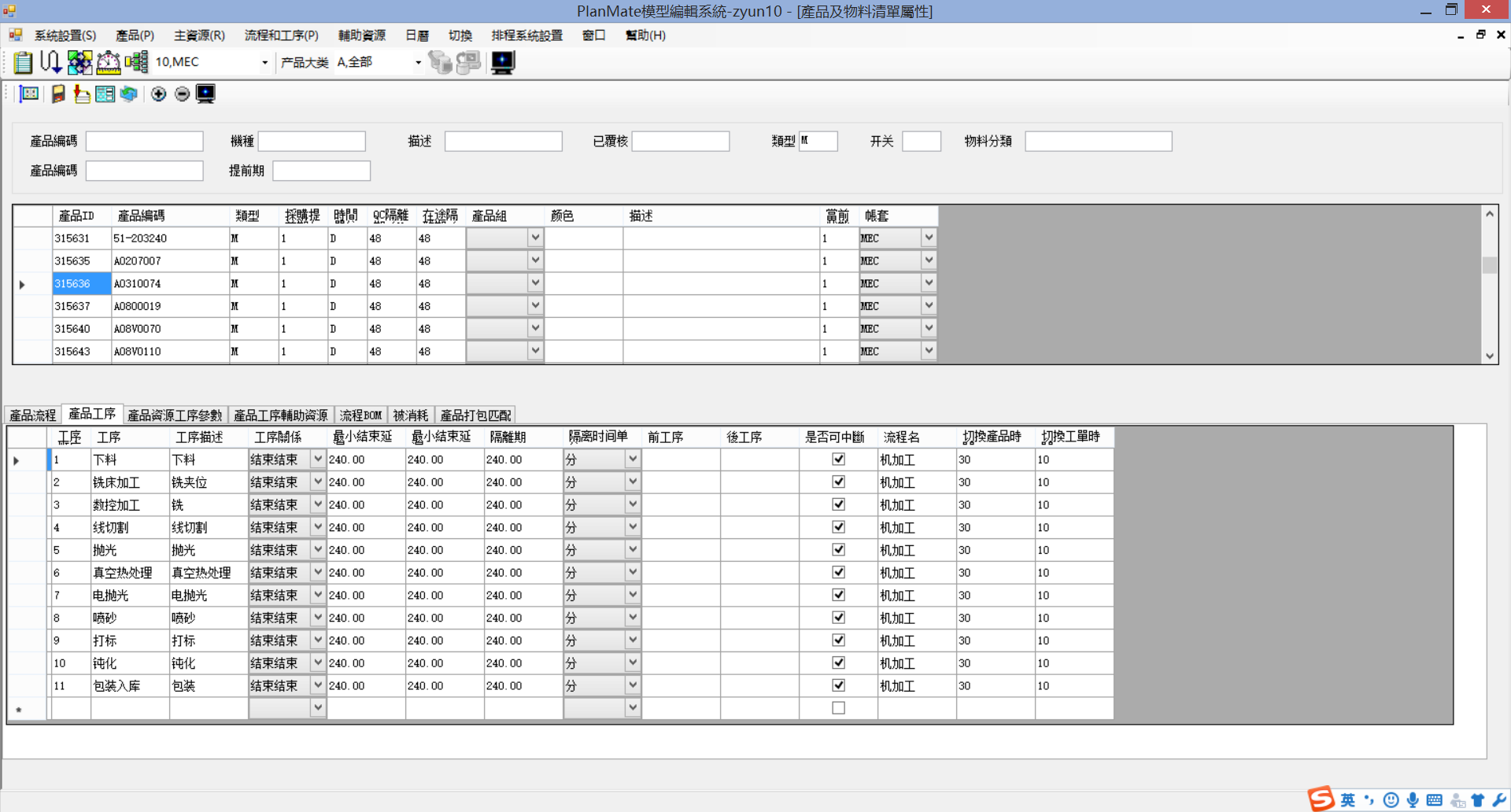

Modeler Modeler:

PlanMateAPS’ Modeler is a Windows application for maintaining process models. Users can collect and organize models in Excel and import models in the modeler. Modelers can also be used to export models from the database to Excel.

PlanMate series products ESOP and MES share modelers with APS. The model structure is easily extensible and the user interface definable.