Safety stock is additional inventory that a business maintains to meet demand and supply uncertainties. Safety stock includes manufactured and purchased parts. The management and optimization of safety stock are an integral part of supply chain management software. As IT systems, including ERP and MRP, they need to have decision support capabilities to help companies formulate reasonable inventory strategies and calculate reasonable inventory quantities for each material.

The goal of supply chain optimization is to maximize profits. Enterprises must weigh the pros and cons in saving inventory costs, increasing capital turnover, and ensuring material supply to maximize profits. Simply focusing on low inventory or low material shortages is not the best option.

The calculation of safety stock includes the principles and algorithms of probability theory and mathematical statistics. In addition to algorithms, the statistics of historical data and demand forecasting are the biggest difficulties. In ERP and MRP, all historical data will be saved in the system. In principle, the statistics of historical demand can be realized, but demand forecasting is affected by too many factors, including seasonal off-peak and peak seasons, market growth factors, and product category changes. , policy factors and other aspects, it is relatively difficult and requires more manual experience.

If the ERP system’s decision support capability is weak, companies can only use simple empirical methods. However, simple empirical methods cannot guarantee rationality and cannot maximize the overall interests of the supply chain. In order to make up for the shortcomings, Ruite Technology’s MRP system provides a safety inventory management function, which is connected with the ERP data. It can make statistics on the historical data in the ERP and calculate the safety inventory based on the product satisfaction rate. ?APS will also use safety stock data to generate procurement recommendation plans during material analysis and material demand calculations. Users can compare the safety stock value calculated by MRP with the experience value and adjust the set stock value in ERP.

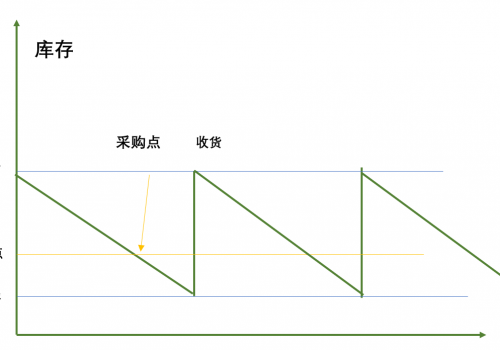

The inventory curve usually looks like this: