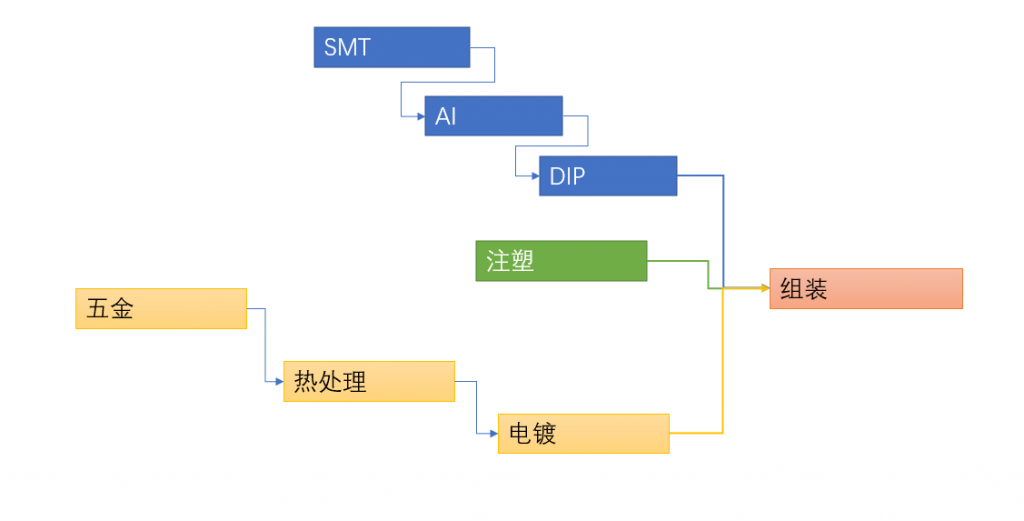

A salable finished product is expanded layer by layer according to the BOM and is divided into multiple levels, so the BOM is called a tree structure. In ERP, each node at the BOM level will open a separate work order.

Production scheduling scheme for multi-level work orders in APS system

Problem Description

Since the production processes of parts and components at each node are different and the production cycle is long or short, the number of work orders at each node is very different. Products with short production cycles will be merged into work orders, while products with long production cycles will not be merged, and work orders will sometimes be split to a length of time suitable for production.

Customers often modify the quantity and delivery date of orders, and scrapping may occur during production. After a period of time, the matching relationships between order work orders and between work orders at all levels will become chaotic. Since ERP does not track the matching relationships between work orders at all levels, PMC needs to check materials and calculate demand layer by layer when manually preparing production plans. This not only makes PMC’s work cumbersome, but also prone to errors. , the adverse consequences caused are:

- When assembling finished products, it is often found that the quantity of some parts is insufficient and the required quantity cannot be assembled.

- After some parts are produced, they are not used for a long time in the post-processing process, which increases the inventory. Some parts become dead materials and are forced to be scrapped.

PlanMateAPS Solution

In PlanMateAPS, work order management is an important function. The specific method is to match the work orders at all levels and establish the before and after constraint relationships before the Solver runs automatic scheduling.

After matching, the system gives the following report:

- Suggestions for re-opening work orders: If the number of work orders is insufficient, the system will give suggestions for re-opening work orders, and users need to go to the ERP to re-open work orders.

- Work order splitting suggestions: If the demand date span of a work order is too large, the system will give splitting suggestions.

- Recommendation for merging work orders: If there are multiple work orders with small quantities on similar demand dates, the system recommends merging them

- Suggestions for reducing work orders: The number of some work orders exceeds the needs of superiors and needs to be reduced

APS cannot replace ERP to change work orders. Users need to make changes to work orders in ERP. Some ERPs do not support splitting work orders. You can reduce the quantity first and then open new work orders.

After the work order change is completed, you need to re-import the work order, run the work order matching again, and establish a new constraint relationship.

During scheduling, PlanMateAPS establishes the front and back constraints of tasks according to matching relationships, and combines multiple work order tasks together during the assembly phase.