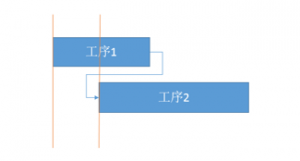

Features of batch production scheduling:

The capacity of each batch is certain. Where the process permits, furnace production should be combined as much as possible to improve equipment utilization.

- The production process cannot be interrupted. For flow production equipment, tasks will be stretched during rest periods. Batch production cannot be interrupted, and breaks must be completed continuously and cannot be extended.

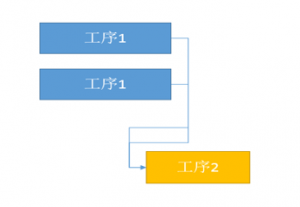

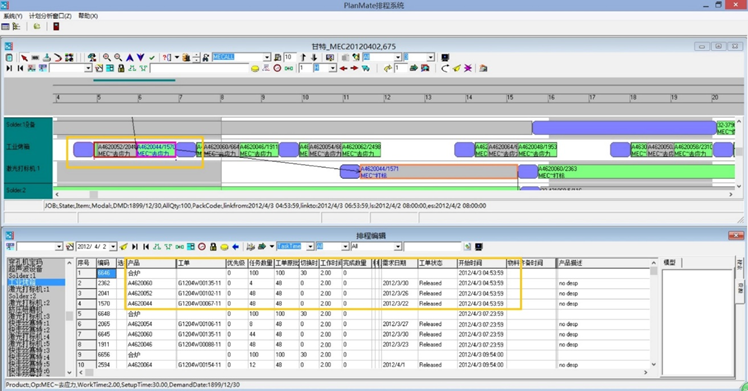

2.In the equipment scheduling of batch production mode, the furnace volume is determined, but the batch size of work orders varies greatly. In order to improve efficiency, large work orders are split into multiple furnaces, and small orders are produced in one furnace.

Different equipment has different calculation methods for heat size. The projects we have encountered are mainly divided into three categories:

- Fixed quantity: For example, in vacuum evaporation equipment, the number of holes on the workpiece plate is fixed. If the product sizes are the same, only the quantity needs to be considered.

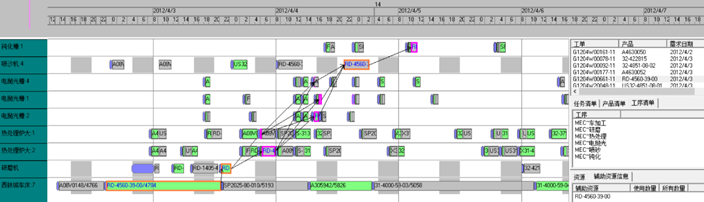

- Calculated by equipment capacity: Each product does not need to use a specific jig during production, only the total capacity needs to be considered, such as large ovens, heating furnaces and other equipment. However, since the product size varies, it must be calculated based on the size of the product.

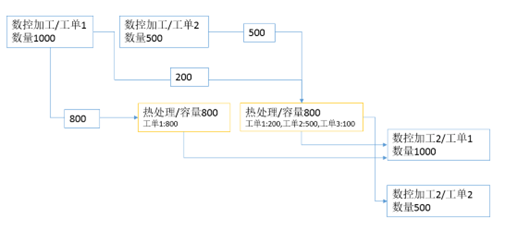

This type of equipment can define the total capacity of the equipment and define dimensional parameters for the product. Combine production according to parameters such as equipment capacity, product size, and number of work orders.

Example:

Suppose a heating furnace has a capacity of 500 based on standard size products, that is, the product size is 1 and 500 can be placed. If the product size is defined as 2, 250 pieces can be placed. Assuming that 200 products of size 1 have been placed in a furnace, the remaining capacity can be placed for another 150 products of size 2.

The definition of product size is not necessarily an integer, it can also be defined as a decimal. The number of products that can be placed = total capacity/product size.

- Calculated based on the jigs that can be installed on the equipment, the following figure shows four workpiece trays assembled into one furnace. Each workpiece tray has multiple holes. Each hole can be installed with one jig, and each jig can be installed with 1. or multiple products.