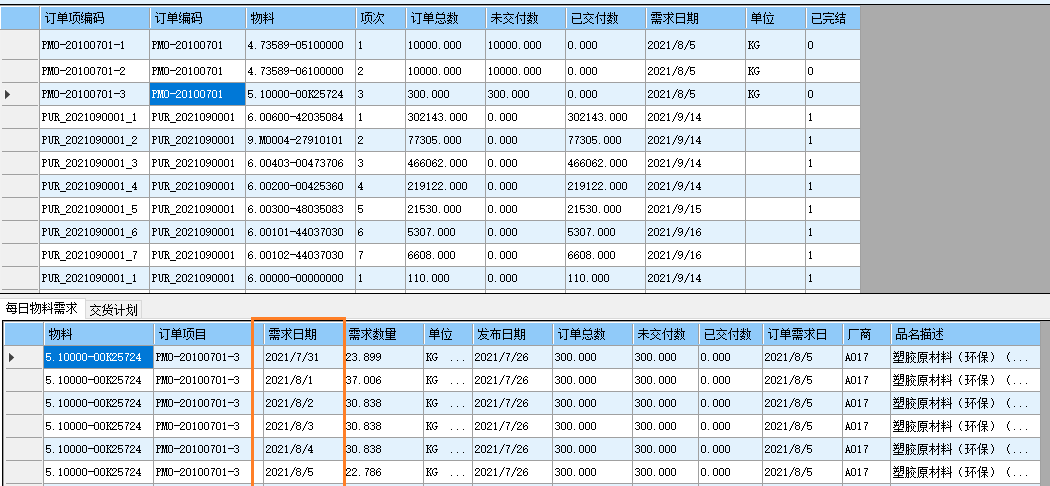

When the MRP system places an order, the algorithm is based on: actual order demand + safety stock. However, the basis for MRP system procurement is the demand time of the order, which is not necessarily consistent with the actual production time.

Consider an extreme situation. If the order demand is based on a monthly basis and this month produces the demand for the next month, how to purchase materials? Do you want to purchase all the materials needed for a month at the beginning of the month? This will inevitably lead to excessive inventory levels.

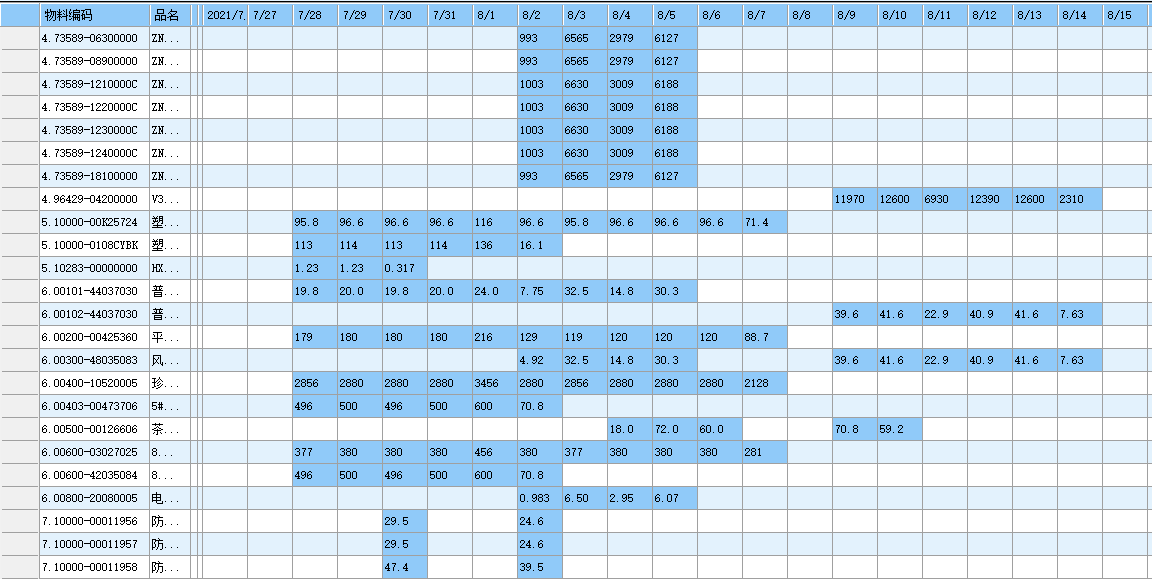

By importing APS, we can conduct detailed production scheduling for all monthly orders, determine the expected production date of each order, refine the demand time and quantity, and allow suppliers to deliver goods according to the actual demand date. This can not only greatly reduce inventory levels, but also ensure supply of production materials.