Set analysis is an important function in the APS system. The set analysis includes both manufactured and purchased parts. The complete set of manufactured products involves the production plan of semi-finished products, and the complete set of purchased parts is calculated based on in-stock inventory and in-transit inventory.

Here we give an example of a suite of analyses:

Example 1: Material collection date for a single order

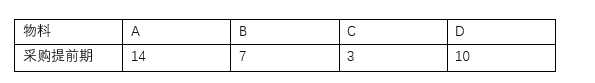

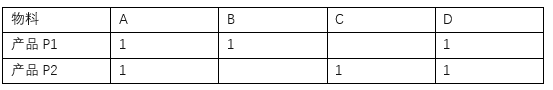

Assume that the materials of product P include four purchasing parts A, B, C, and D. Their purchasing lead times are as follows:

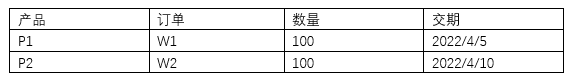

We assume that the order quantity of P is 100. To simplify the calculation, assume that the consumption of various materials is 1, and the current day is 2022/4/1

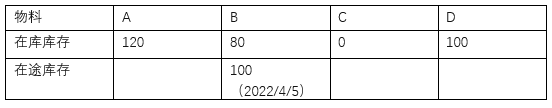

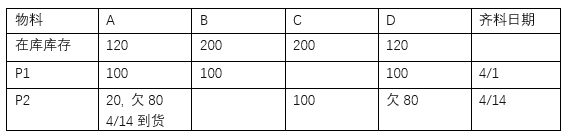

Assumption 1:

Inventories in storage and in transit are as follows:

The above calculation is based on B’s arrival date, and the order’s delivery date is 4/5. Although C is short of materials, the lead time is 3 days, and the estimated arrival date is 4/3, which is earlier than 4/5.

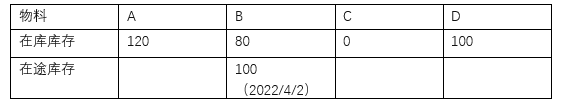

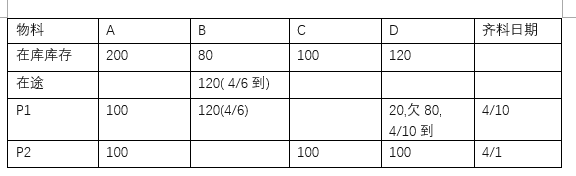

Assumption 2:

B’s arrival date is April 2nd, C is out of stock, but the procurement lead time is 3 days. Assume that the purchase order is placed today and the goods can arrive on April 3rd, then the order’s materials collection date is April 3rd.

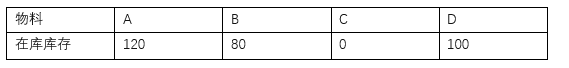

Assumption 3:

The above B and C are all in short supply. The date of material collection is calculated based on the larger lead time. The date of material collection is 4/7.