The management of safety stock is an important function in the ERP system. However, due to the complexity of demand analysis and calculation, many companies use simple empirical methods for inventory procurement, and it is difficult to ensure the rationality of safety stock levels. In this article we give a general algorithm for safety stock based on probability theory. Both RateMRP and PlanMateAPS systems provide algorithms to calculate safety stocks.

First understand several basic factors that affect safety stock:

1. Expected product availability level: For a certain demand, the proportion of inventory meeting demand, there are several evaluation indicators:

-

- Product satisfaction rate: the probability that a product will not be out of stock during a replenishment cycle

- Order fulfillment rate: the probability that an order will not be out of stock during a replenishment cycle

- Cycle service level: among multiple non-replenishment cycles, the proportion of cycles in which no out-of-stock occurs

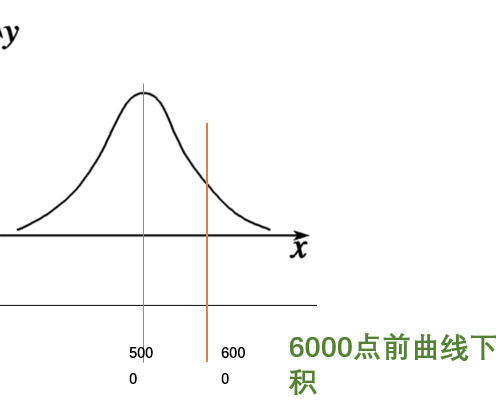

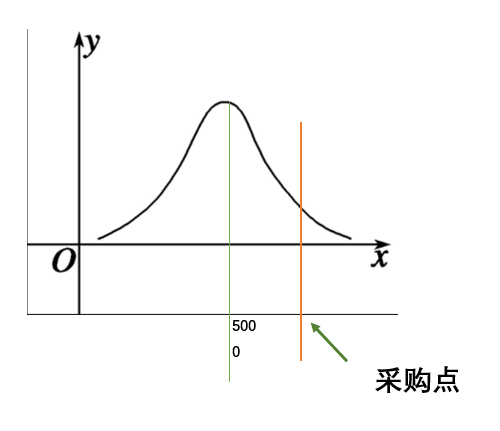

2. Uncertainty of demand: changes in demand satisfy the normal distribution. The greater the uncertainty in demand, the greater the safety stock required.

3. Uncertainty of supply: There is also uncertainty in the lead time of supplier supply.

Both demand and supply satisfy normal distribution. The basic parameters are as follows:

- Average: M=(x1+x2+x3+…+xn)/n

- Variance: S?=〈(M-x1)?+(M-x2)?+(M-x3)?+…+(M-xn)?〉╱n

- Standard Deviation: Square Root of the Variance

- Coefficient of variation: standard deviation/mean

4. Inventory replenishment strategy:

- Continuous inventory: Issue purchase orders upon arrival at the order point. The purchase quantity remains unchanged but the purchase cycle changes.

- Cycle counting: Fixed cycle procurement, the quantity of each purchase changes