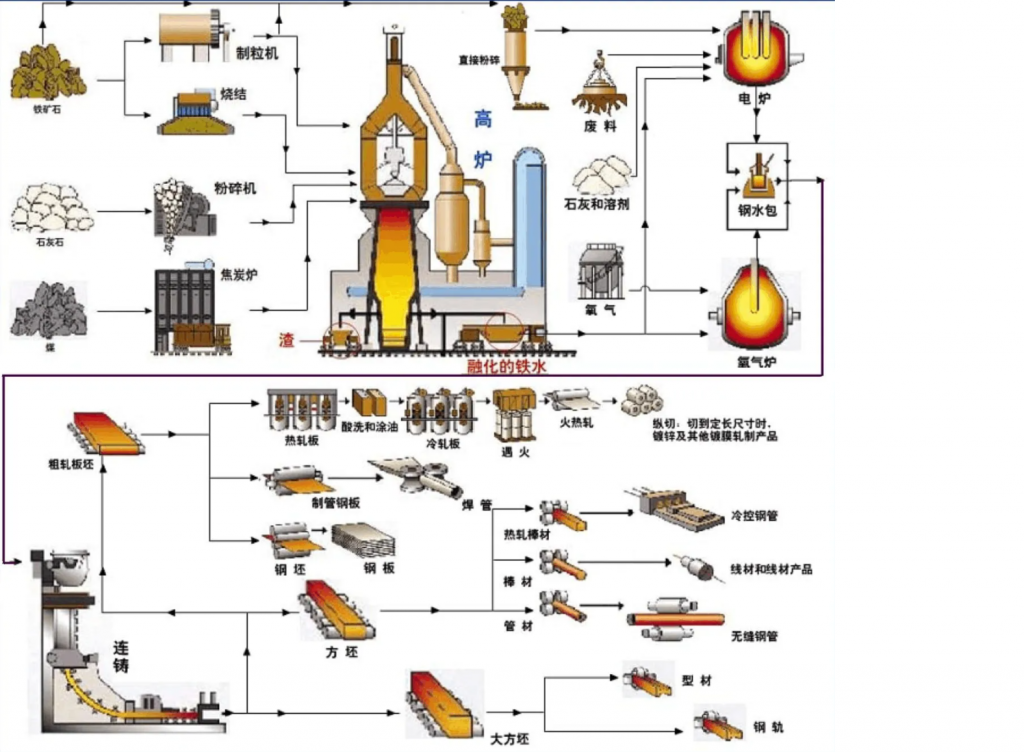

Pouring/rolling:

Divided into hot rolling and cold rolling. Hot rolling directly receives the molten steel produced by steelmaking. When scheduling, the appearance size and material of the product are mainly considered, such as the width of the slab, the length and width of the steel column, the diameter of the steel pipe, etc., so that various specifications can be continuously changed slowly, in increments Or decreasing emissions. In addition, the output plan must match the output speed of molten steel.

Cold rolling uses plates that have been put into storage, and production plans use inventory. When scheduling, we mainly consider the order delivery date, rolling temperature and specifications of various products, so that the temperature changes steadily and the specifications change slowly and continuously to meet the order delivery date.